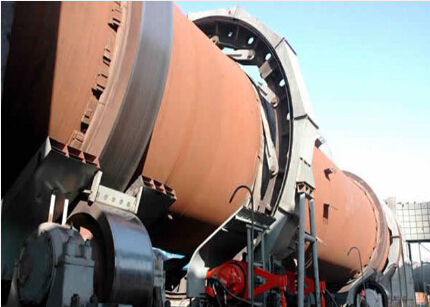

high efficiency dryer

Description

The efficient & energy saving dryer is mainly used for drying the materials with specified granularity and humidity. Having the strong adaptability it

can be applied for various materials with its reliable and convenient operation. The machine is composed mainly by rotary part, lifting plates,

transmission unit, support device and sealing ring. This dryer, manufactured by Y.H. Heavy has advantages of reasonable structure, elaborate

manufacturing, big capacity, low energy consumption and easy handling etc.

Volume of drum:9.0-285m³

Capacity:1.9-76t/h

Application: Various industries of ore grading, construction materials, metallurgy, chemical industry and foods etc.

Suitable materials: slag, limestone, coal powder, coal mud, lignite, clay and bauxite etc.

立即订购

立即订购

产品特点

1、 Advanced technology adopted to reduce the dust removal load

The novel feeding and discharging devices are adopted to avoid the blocking, non-continuity, non-uniformity and reverting of materials

of the drum dryer and reduce therefore the working load of dust removal system.

2、 Concurrent flow drying method, high thermal efficiency

The concurrent flow drying method is applied for the dryer made by Y.H.Heavy. The flue gas and wet materials are fed into the dryer

from the same side. The high evaporation intensity can be obtained by high temperature of flue gas. The exit temperature of dryer is low with

the performed heat efficiency.

3、 Low wear rate, steady running

The “zero horizontal thrust” has been achieved by the dryer reducing greatly the wear of thrust shaft to ensure the steady running of the

dryer. The “ centering type support roller” is adopted to have always the lineal contact between support roller and tire in order to decrease the

wear and power consumption maximum.

4、High automation extent, convenient operation

The running parameters which are changed as per nature of materials will make the materials forming a stable full section materials curtain

in the dryer to get the heat exchange more fully. And the moisture index can be easily adjusted on basis of customer requirement.

5、 Anti-overload ability, low drying cost

The dryer is featured by its strong anti-overload ability, big handing capacity, low consumption of combustibles and low drying cost.

工作原理

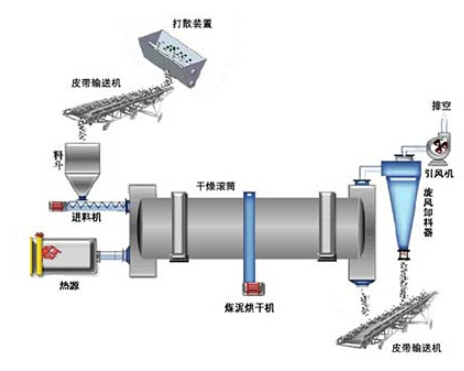

spiral progressive type to make the heat exchanges. Then the materials move to the another side of inner drum to be ready to enter

into the middle drum in order to have the counter-current drying. In the middle drum, the materials are constantly lifted and move forward in type

of “two steps advance & one step back”, there the materials absorb not only the heat dissipated from the inner drum, but also the heat from the

middle drum, as so the drying time is prolonged and the optimal drying conditions can be obtained.

Then the materials move to the another end of the middle drum and fall down on the outer drum. In the outer drum, the materials move forwards

in “rectangular & multi loop mode”. The materials which achieve the drying effect fast march and discharge out under the action of hot air; and

the other ones which don’t achieve the drying effect (rather wet) can’t march fast due to the gravity, thus these materials must be dried fully in the

rectangular lifting plates to complete the drying process.

技术参数

|

Type(mm) |

Inclination(%) |

Inlet temperature(℃) |

Rotary speed(r/min) |

Power(kw) |

Capacity(t/h) |

Weight(t) |

|

Ф600x6000 |

3-5 |

≤700 |

3-8 |

3 |

0.5-1.5 |

2.9 |

|

Ф800x8000 |

3-5 |

≤700 |

3-8 |

4 |

0.8-2.0 |

3.5 |

|

Ф800x10000 |

3-5 |

≤700 |

3-8 |

4 |

0.8-2.5 |

4.5 |

|

Ф1000x10000 |

3-5 |

≤700 |

3-8 |

5.5 |

1.0-3.5 |

5.6 |

|

Ф1200x10000 |

3-5 |

≤700 |

3-8 |

7.5 |

1.8-5 |

14.5 |

|

Ф1200x12000 |

3-5 |

≤700 |

3-8 |

11 |

2-6 |

14.8 |

|

Ф1500x12000 |

3-5 |

≤800 |

2-6 |

15 |

3.5-9 |

17.8 |

|

Ф1800x12000 |

3-5 |

≤800 |

2-6 |

18 |

5-12 |

25 |

|

Ф2200x12000 |

3-5 |

≤800 |

1.5-6 |

18.5 |

6-15 |

33 |

|

Ф2200x18000 |

3-5 |

≤800 |

1.5-6 |

22 |

10-18 |

53.8 |

|

Ф2200x20000 |

3-5 |

≤800 |

1.5-6 |

30 |

12-20 |

56 |

|

Ф2400x20000 |

3-5 |

≤800 |

1.5-5 |

37 |

18-30 |

60 |

|

Ф3000x20000 |

3-5 |

≤800 |

1.5-5 |

55 |

25-35 |

78 |

|

Ф3000x25000 |

3-5 |

≤800 |

1.5-5 |

75 |

32-40 |

104.9 |

.jpg)