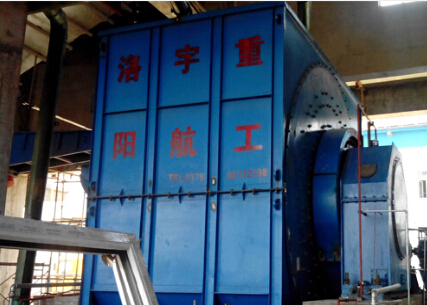

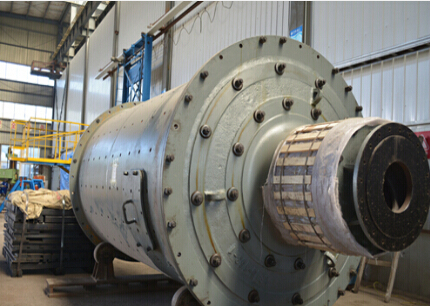

screening and grinding mill

Based on the successfully used of the alumina crust block grinding system, our company has improved and patented this new screening & grinding mill system, which is used to the products of different granularity between 4 ~20mm. This system integrating the screening with grinding has features of simple structure, low cost, high efficiency and big capacity.

立即订购

立即订购

产品特点

1、 More reliable system

The traditional process equipment is featured by its low efficiency, laggard level of automation, insufficient reliability and unstable capacity. While the screening and grinding system because it’s equipped with the advanced control system, and uses fully the beneficial factors of grinding technology in the design stage, has well performed in continuous running and reliability.

2、 Low cost on maintenance

Due to the old technology and structure of the traditional process, the advanced monitor and control system can not be integrated with the old system, so its level of automation is backward increasing thereby the load of maintenance and quantity of relative personnel. And the screening and grinding system is equipped with the automation system of higher degree which decease greatly the cost of maintenance.

3、Handling capacity increased by 30%, installed power decreased by 50% and low cost of running

The traditional system adopts process of the two crushing stages and the screening to achieve the product granularity, but there are disadvantage of parts frequently damaged and the dust leakage. While the screening and grinding mill - the main equipment of the system is multi-function machine which can not only grind the materials, but also screen them. The handing capacity of this system is 30% higher than the traditional one, and the installed power decreases by 50%, so as to greatly decrease the running cost.

4、Solid structure, steady running, good dust collection effect

Compared with the traditional process, the screening & grinding mill adopts the mature and advanced hydro-static sliding bearing and the chain transmission which is more solid and stable. The frequency variable motor is used as main motor of the mill to create the conditions for decreasing the start current and facilitate the trial test of the equipment. The rotary parts is enclosed in the shell, which reduce the noise of the system and guarantee also the dust collection effect.

.jpg)