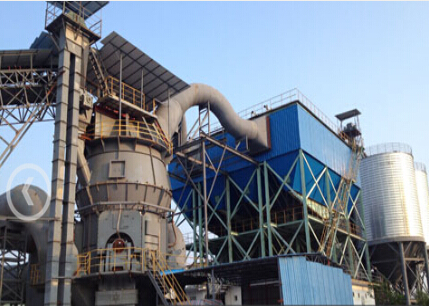

vertical mill

The vertical mill

application:

Mineral power production line, mineral waste production line, coal power production line, those metal and non-metal mines.

Suitable material:

Raw material, clinker, slag, iron ore, limestone, coal powder, coke, coal gangue, fly ash, gypsum, calcite, pyrophylite, quartz, clay, gravel, bauxite, silica fume, metal and non-metal ores.

features:

The grinding efficiency is high and the electricity consumption is low.

The metal consumption is low.

The powder bed is used to grind the material with low noise.

The dust pollution is decreased due to the pressure operation.

The technical process is simple and grinding, drying and powder selecting function can be achived simultaneously.

Small occupation area, compact design, the weight of the system equipment is light, and the investment to the land construction is low.

立即订购

立即订购

产品特点

Characteristics

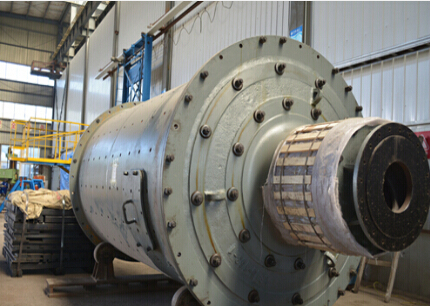

1. Efficient grinding, low power consumption

2. Low metal consumption per unit product

3. Bed-grinding with low noise

4. Negative operation with small dust pollution

5. Simple grinding process to achieve the grinding, drying and powder separating simultaneously

6. Small occupied area, compact design , light weight and low investment to the land

construction.

工作原理

The materials fall down via the discharge chute in the center of grinding disc, which rotates at constant speed distributes evenly the materials outwards by the centrifugal force to form the materials bed with a certain thickness to be crushed then by the grinding rollers. Next the material move under the continuous centrifugal force, forwards to outer edge of the disc. After ground the materials leave the disc, lift with the hot air prior to be fed in the mill, and enter into the separator through the mill center. During this process, the full heat exchange has been completed between the materials and hot air in order to evaporate quickly the moisture.

The separator determines the product granularity from the roll mill. The sizes over the specified ones will be separated and returned back to the disc for regrinding, and the sizes which meet the fineness requirement will be sent to the collector and then to the product silo.

.jpg)