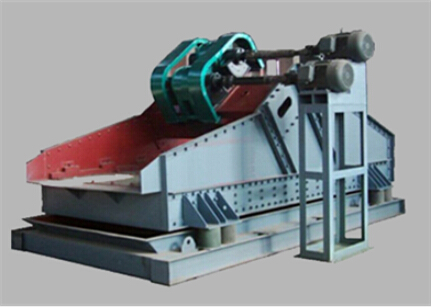

round vibrating screen

Round vibrating screen is a round, multi-layers, high-performance & new-type vibrating screen. It uses the eccentric shaft exciter and the eccentric block to adjust the amplitude. It has many advantages, such as the reliable structure, strong exciting force, efficient screening, low vibrating noise, sturdy and durable, easy maintenance and safe in operation etc. It is widely used in mine, building material, transportation, energy, chemistry and other fields for classification.

Max. Feeding size: 400mm

Handing capacity: 8-800m³/h

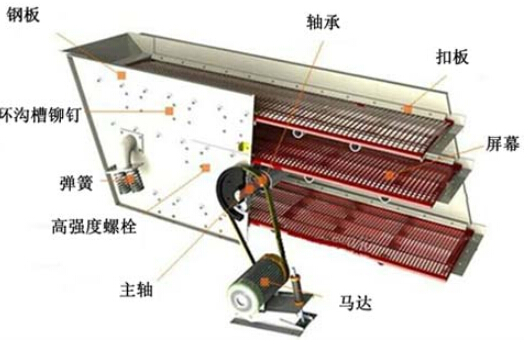

Composition: Sieve box, mesh, vibrator, damper spring, frame, hanging (support) device and motor

Application: Widely used for materials classification in industries of mine, building materials, communication, energy and chemical industry etc.

Suitable materials: shale, coal, mica, baritic rock, feldspar, etc.

PRODUCT FEATURES

Features:

1.Efficient screening.

For the material that is not easy to be screened, the round vibrating screen can make the main shaft rotate reversely, so that the vibrating direction and the material flow direction are opposite, the material speed that moves on the screen surface will decrease in order to improve the screening efficiency. Furthmore the screen surface angle can be adjusted to make the material speed change accordingly to improve the handling capacity.

2.Simple structure and easy to operation

3.The simple structure of screen is adopted to improve the manufacturing process & assembly accuracy, and the operation effectiveness can be raised with easy operation and maintenance.

4.Long service life & low maintenance rate

5.The vibrating force is strong and stable without serious shaking. The fault rate is very low which reduces repair and maintenance works. It also has other advantages, such as big handling capacity, long lifespan, low energy consumption and low repair cost etc.

WORKING PRINCIPLE

Working principle:

There are hanging type and sit type supports for round vibrating screen. The sieve of hanging type is fixed on sieve box hanged or supported by spring. Main shaft, whose bearing is also mounted on sieve box runs at high speed driven by pulley. The eccentric disc on the main shaft runs with shaft to produce the centrifugal inertia force making the sieve box have thus the vibration of approximate circular tracks. The distance between the eccentric weight and center line of bearing is an exciting eccentricity.

TEHNICAL PARAMETERS

|

Type |

Nos. of layer |

Screen angle (°)

|

Screen area (m2) |

Vibrating frequency (r/min)

|

Double - amplitude |

Capacity (m3/h)

|

Motor power (kW) |

Overall dimension (L×W×H) |

Weight (kg) |

|

YK1235 |

1 |

15 |

4.2 |

970 |

6-8 |

35-180 |

5.5 |

3729×2443×1547 |

1845 |

|

2YK1235 |

2 |

15 |

4.2 |

970 |

6-8 |

40-150 |

5.5 |

3924×2433×2349 |

982 |

|

3YK1235 |

3 |

15 |

4.2 |

970 |

6-8 |

25-270 |

7.5 |

3924×2527×2713 |

3922 |

|

4YK1235 |

4 |

15 |

4.2 |

970 |

6-8 |

25-270 |

11 |

3934×2688×3126 |

4821 |

|

YK1545 |

1 |

17.5 |

6.75 |

970 |

6-8 |

63-315 |

11 |

4923×2943×2164 |

3362 |

|

2YK1545 |

2 |

17.5 |

6.75 |

970 |

6-8 |

200-300 |

15 |

5163×3090×3156 |

5113 |

|

3YK1545 |

3 |

17.5 |

6.75 |

970 |

6-8 |

35-378 |

15 |

5163×3040×3513 |

6251 |

|

4YK1545 |

4 |

17.5 |

6.75 |

970 |

6-8 |

200-300 |

18.5 |

5163×3155×3804 |

7519 |

|

YK1548 |

1 |

17.5 |

7.2 |

970 |

6-8 |

63-315 |

11 |

5199×2943×2171 |

3418 |

|

2YK1548 |

2 |

17.5 |

7.2 |

970 |

6-8 |

200-300 |

15 |

5449×3090×3201 |

5266 |

|

3YK1548 |

3 |

17.5 |

7.2 |

970 |

6-8 |

35-378 |

15 |

5449×3090×3558 |

6453 |

|

4YK1548 |

4 |

17.5 |

7.2 |

970 |

6-8 |

47-275 |

18.5 |

5449×3155×3909 |

7845 |

|

YK1860 |

1 |

20 |

10.8 |

970 |

6-8 |

52-567 |

15 |

6302×3390×2992 |

4572 |

|

2YK1860 |

2 |

20 |

10.8 |

970 |

6-8 |

200-300 |

18.5 |

6020×3455×3756 |

5808 |

|

3YK1860 |

3 |

20 |

10.8 |

970 |

6-8 |

52-567 |

18.5 |

6020×3455×4180 |

7349 |

|

4YK1860 |

4 |

20 |

10.8 |

970 |

6-8 |

52-567 |

22 |

6183×3545×4521 |

8809 |

|

YK2160 |

1 |

20 |

12.6 |

970 |

6-8 |

200-300 |

18.5 |

6302×3755×2992 |

4940 |

|

2YK2160 |

2 |

20 |

12.6 |

970 |

6-8 |

66-720 |

22 |

6184×3755×3814 |

6438 |

|

3YK2160 |

3 |

20 |

12.6 |

970 |

6-8 |

66-720 |

30 |

6184×3915×4239 |

8665 |

|

4YK2160 |

4 |

20 |

12.6 |

970 |

6-8 |

66-720 |

30 |

6176×3915×4521 |

9933 |

|

YK2460 |

1 |

20 |

14.4 |

970 |

6-8 |

200-300 |

18.5 |

6302×4105×2992 |

5496 |

|

2YK2460 |

2 |

20 |

14.4 |

970 |

6-8 |

79-864 |

30 |

6184×4265×4032 |

8090 |

|

3YK2460 |

3 |

20 |

14.4 |

840 |

7-9 |

79-864 |

30 |

6184×4284×4510 |

11255 |

|

4YK2460 |

4 |

20 |

14.4 |

840 |

6-8 |

79-864 |

30 |

6181×4284×4787 |

13400 |

ONLINE ORDERING

HENAN LUOYANG

Luoyang Yuhang Heavy Industries Co., Ltd.Headquarters Address: Advanced Manufacturing Cluster Area, Luoyang, china.

Tel: 0379-62112728

0379-64237398

Post code: 471003

E-mail: mail@lyyhzg.com

Chinese official l website: Http://www.lyyhzg.com

English official website: www.yuhang-china.com