-

Website information update..

special crusher for whole piece residual anode carbon

Most enterprises in carbon industry adopt the 500 tons oil crusher. When it’s used for crush the residual anode carbon, the time for crushing one piece is longer (about 2~3 minutes). In addition, the oil pipes of hydraulic system are more complex making the sealing conditions not satisfactory and oil leakage occurs often. So the frequent maintenance is required resulting in the decreased efficiency and extremely high cost. The technicians of our company visited many customers and carried out the detailed study and analysis of the structure of large jaw crusher, and after repeated test, they have successfully developed the special crusher for whole piece residual anode carbon and obtained the patent certificate No: PUM114194

PRODUCT FEATURES

2. The oiling pump will be used for bearing lubrication, which is easy and convenient.

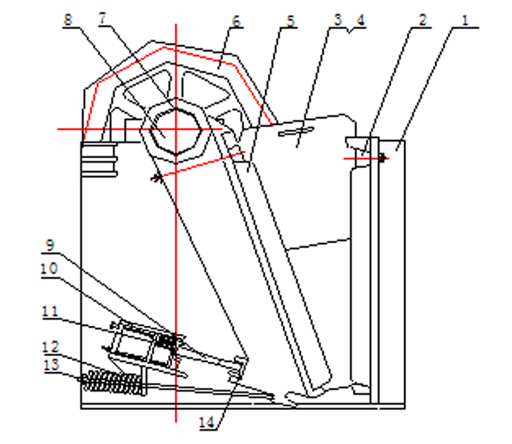

Main structureDwg. 1: Frame

Dwg. 2: Fix jaw plate

Dwg. 5: Movable jaw protection plate

Dwg.6: Flywheel

Dwg.7: Movable jaw

Dwg.8: Eccentric shaft 8

Dwg.9: Thrust plate

This crusher is specially used for the whole piece residual anode carbon, also applied for the rough & middle crushing of various ores or stones with compressive strength less than 250Mps in mining, construction, road and chemical industries etc. This is patented product indepentently researched and developed by our company.

WORKING PRINCIPLE

1. The eccentric shaft driven by the main motor via the triangle belt makes the movable jaw doing the periodic reciprocating motion in order to impact and crush the materials, which will be discharged by the weight itselves.

2. The rack of the crusher is welded by the steel plates. The fix jaw plate is installed on the front, and the side walls are equipped with liners. The movable jaw is welded also by the steel plate on which there is toothed plate pressed by wedge iron. When there is wear on the toothed plate ( usually the lower end is wore more), it can be inverted to be used continually.

3.The front part of the thrust plate is supported on the elbow plate of lower end of the movable jaw, and its bear part is installed on the elbow plate of bear rack. The thrust plate which moves with the movable jaw, will protect the foreign matter from entering in the crushing chamber. That means it can break itself to stop the load in order to avoid the damage on other parts. The shimsets equipped on the bear of the thrust plate are used for adjusting the discharge port.

4.The pull rod (13) and the spring (12) having the locking function will tension the movable jaw and prevent the thrust plate from falling off in order to ensure the normal running of the crusher.

TEHNICAL PARAMETERS

APPLICATION CASE

-

Website information update...

ONLINE ORDERING

HENAN LUOYANG

Luoyang Yuhang Heavy Industries Co., Ltd.Headquarters Address: Advanced Manufacturing Cluster Area, Luoyang, china.

Tel: 0379-62112728

0379-64237398

Post code: 471003

E-mail: mail@lyyhzg.com

Chinese official l website: Http://www.lyyhzg.com

English official website: www.yuhang-china.com