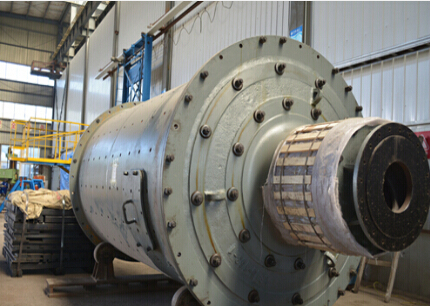

ball mill

The ball mill is key equipment for regrinding the materials after crushed. It’s widely used in many industries such as cement, silicate products, new type construction materials, refractories, fertilizer, ferrous & non-ferrous metal processing as well as glass ceramics etc.

Suitable materials : Dry & wet grinding of various ores and grindable materials.

Sales hot line :0379-62112728

PRODUCT FEATURES

1.The mill is composed essentially by feeding, discharge, rotary and transmission parts (reducer, pinion, motor and electrical control unit). Other main components are: trunnion made by casting; inner lining being replaceaple, girth gear finished by casting and gear-hobbing machining and the wear-resistant liners applicable.

2.Steady running and convenient operation is available. The mill whose diameter is 1500~2100mm adopts the spherical tile main bearing, while the diameter over 2700mm uses the fully enclosed self aligning 120 degree "rocker" type bearing, which has the babbit bush (High lead low tin &low hardness) and cooling pipes in the bearing housing. The bearoning hydrostatic structure is oiled by high & low complex lubricating station.

3. The dry type and wet grate type mill can be selected according to the nature of materials and discharging mode. The ball mill manufactured by our company has three (3) types: wet grate, dry grate and overflow.

WORKING PRINCIPLE

The mill is horizontal drum rotating device. It has features of the girth gear rotating at circumference, two chambers and grate discharging. By feeding device through inlet trunnion the materials are sent evenly & helicoidally in the first chamber which is equipped with stepped liners or corrugates liners, and loaded with the steel balls of different sizes. When the mill works,it will produce the centrifugal force which brings the balls lifting to certain height and falling down to impact and grind the materials. After the rough grinding in the first chamber, the materials enter through the compartment plate in the second chamber where the flat liner is put and steel balls are loaded to regrind further the materials. Finally the crushed materials are discharged by the grate, the grinding process is so completed.

TEHNICAL PARAMETERS

ONLINE ORDERING

HENAN LUOYANG

Luoyang Yuhang Heavy Industries Co., Ltd.Headquarters Address: Advanced Manufacturing Cluster Area, Luoyang, china.

Tel: 0379-62112728

0379-64237398

Post code: 471003

E-mail: mail@lyyhzg.com

Chinese official l website: Http://www.lyyhzg.com

English official website: www.yuhang-china.com