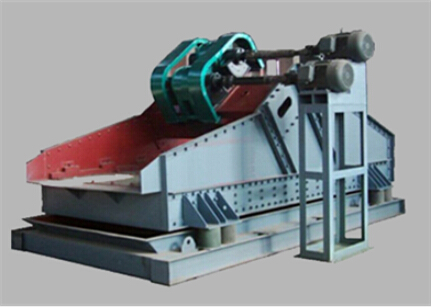

self-centering vibrating screen

Description:

The self-fixed center vibrating screen is used for coarse, middle and fine screening of ores & coal etc. It can be used also for cement and medium removal in materials. This kind of screen is mainly composed by screen box, exciter and hanging (support) device and motor.

His another name is universal hanging screen which is vibrated by eccentric vibrator. It has the following properties: 1). Materials on the sieve can be well loose and layered under the vibrating action; 2). Counterweight of screen can be adjusted, and according to production rates to adjust the vibration amplitude; 3). Amplitude changes on basis of feeding rate. When the feeding rate is small, the amplitude increases, conversely the feeding rate is larger, the amplitude decreases. The feeding rate change will impact the “dynamic balance” resulting in some vibration in belt wheel center; 4) Suitable for screening of middle and fine materials.

Applications:

The self-fixed center screen, widely used for materials classification in various industries such as mine, coal, metallurgy, construction materials, refractory materials, light industry, medicine and foods etc., is ideal equipment in crushing & screening system. As it operates with circular traces, it has characteristics of simple structure, durability, good performance, easy for maintenance and efficient screening.

Its advantages include also: hanging type and sit type installation; movable frame equipped for small screen; single and multi-layers sieves; transmission installed in left or right; as well as metal woven wire and punching sieves used as screen sieves.

PRODUCT FEATURES

Characteristics:

1. Big amplitude and efficient screening

2. Wear-resist rubber sieve available, its service life is 10~20 times of steel fabricates and 4~6 times of polyurethane.

3. High Elasticity & wear-resistant rubber spring available, it has long service life and low noise.

4. Seat-type and hang type vibrating screens available.

WORKING PRINCIPLE

Working principles:

The motor, through pulley drives the eccentric shaft, this one is connected with screen box. The centrifugal inertia force produced by eccentric shaft will make the screen box do the vibration with circular traces. Due to eccentricity of axle hole of big belt wheel, the central distance between big & small wheels is kept no change.

TEHNICAL PARAMETERS

|

Type |

Size |

Max. Feeding size (mm)

|

Handling capacity (t/h)

|

Motor |

Power (kw) |

Weight |

Remark |

|

Type |

(kg) |

||||||

|

SZZ0918 |

900×1800 |

40 |

20~25 |

Y100L1-4 |

2.2 |

420 |

Hanging type |

|

SZZ0918 |

553 |

Sit type |

|||||

|

2SZZ0918 |

570 |

Sit type |

|||||

|

SZZ1225 |

1250×2500 |

100 |

100 |

Y132S-4 |

5.5 |

1020 |

Hanging type |

|

SZZ1225 |

1330 |

Sit type |

|||||

|

2SZZ1225 |

1320 |

Hanging type |

|||||

|

2SZZ1225 |

1335 |

Sit type |

|||||

|

SZZ1530 |

1500×3000 |

200 |

Y132M-4 |

7.5 |

1650 |

Hanging type |

|

|

SZZ1530 |

1700 |

Sit type |

|||||

|

2SZZ1530 |

2870 |

Hanging type |

|||||

|

2SZZ1540 |

1500×4000 |

100 |

250 |

Y160L-4 |

15 |

4240 |

Sit type |

|

SZZ1836 |

1800×3600 |

150 |

300 |

Y180M-4 |

18.5 |

4500 |

Hanging type |

|

2SZZ1836 |

5616 |

Sit type |

ONLINE ORDERING

HENAN LUOYANG

Luoyang Yuhang Heavy Industries Co., Ltd.Headquarters Address: Advanced Manufacturing Cluster Area, Luoyang, china.

Tel: 0379-62112728

0379-64237398

Post code: 471003

E-mail: mail@lyyhzg.com

Chinese official l website: Http://www.lyyhzg.com

English official website: www.yuhang-china.com